mass flow controller working principle

Industrial MFCs are usually standard at 1500 psi 100 bar and can be made to withstand 4500 psi 300 bar pressure sometimes. It is possible to control the flow rate stably with high accuracy because it is not required to be corrected due to the change of temperature or used pressure.

Horiba Fluid Measurement Control Mass Flow Controller

These devices are essential to most thermal and dry etching processes.

. Two programmable mass flow rate totalizers. With RS485 Output 0 to 5 V DC Control Input Signal. Advanced Energy s Aera MFCs provide the most.

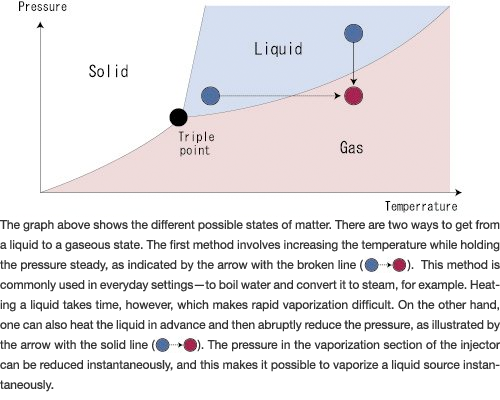

A mass flow controller MFC is a device used to measure and control the flow of liquids and gases. Some MFCs are limited to 100 psi or 500 psi maximum working pressures. Working principle of thermal Mass Flow Meters Controllers.

Although volumetric flow under nominal conditions may be accurately calculated the process conditions and fluid properties can vary sufficiently such that it is questionable if the measured volumetric flow rate or derived. The relationship between mass flow and volumetric flow is as follows. High Low or In Range Alarms with preset action delay for Mass Flow Temperature and Pressure.

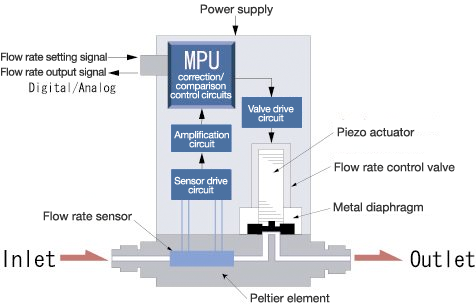

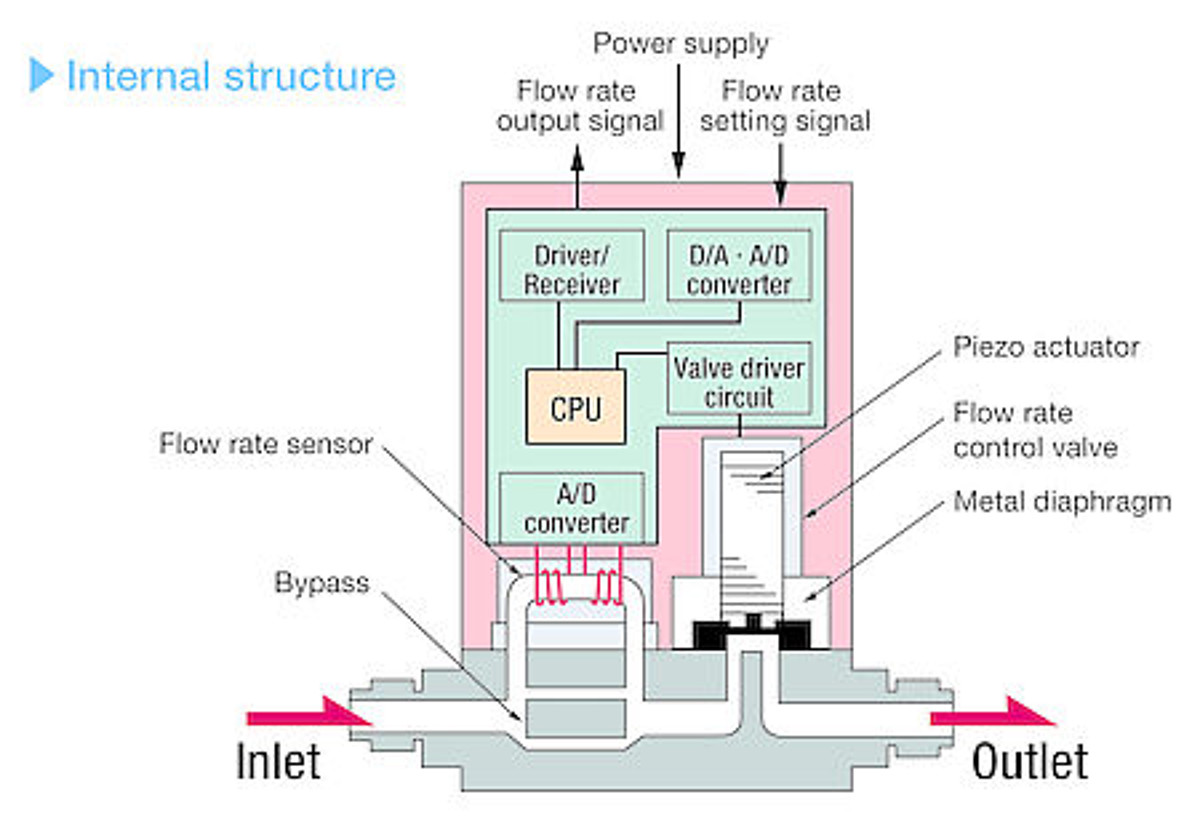

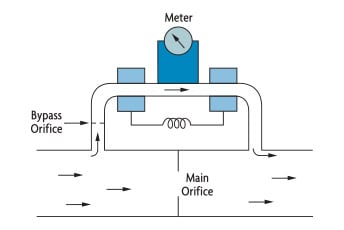

A mass flow controller is a device used to control the flow rate by measuring the mass flow rate of fluid and gases. The MFC can be given a setpoint from 0 to 100 of its full scale range but is typically operated in the 10 to 90 of full scale where the best accuracy is achieved. The thermal gas mass flow controller is composed of a flow sensor a diverter channel a flow regulating valve and an amplifier controller.

Chlorine air and compressed air can reach it. No part of this work may be reproduced or transmitted in any form or by any means electronic or mechanical including photocopying and recording or by any information storage or retrieval. The relayed information tells the control system to either turn on or off.

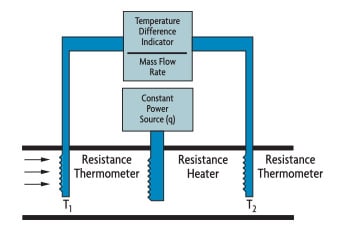

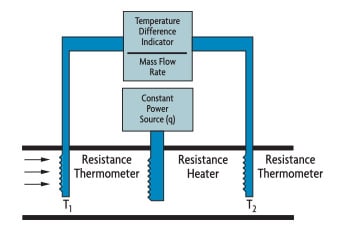

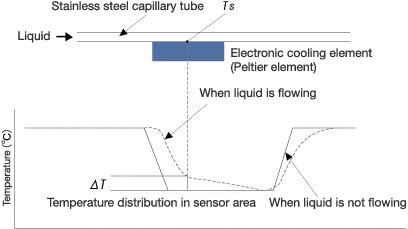

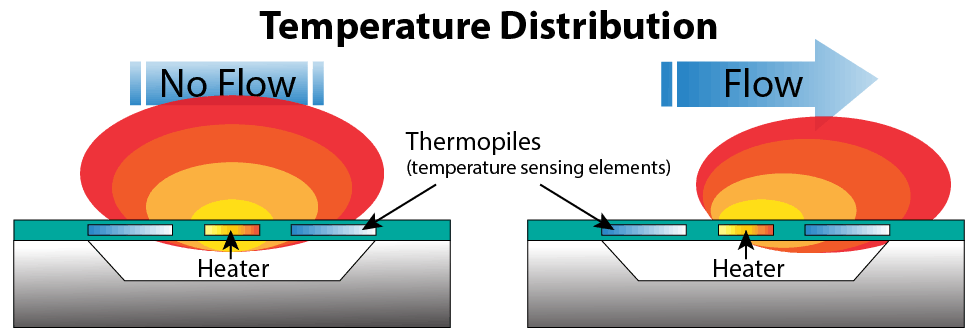

The gas flow sensor uses the principle of capillary heat transfer thermocalorimetry to measure the mass flow of gas without temperature and pressure compensation. Mass flow controller experts from Brooks Instrument detail four key considerations for evaluating selecting the right mass flow controller. Guideline for Pressure Specifications of the Mass Flow Controller 11 SEMI E56-00-1296.

The gas is input from an Inlet joint and is divided so that it flows over both the flow rate sensor and a bypass. 10 reading 05 full scale accuracy repeatability 02. Mass Flow Rate Density x Volumetric Flow Rate.

The standard minimum flow rate of the micro gas mass flowmeter is 2mlmin. The sensor measures the mass flow rate of the gas. The turbines are mounted on a single shaft and are connected with a calibration torsion piece that is flexible.

Extensive Self Diagnostics with status LED or OLED indication. Twin Turbine Mass Flow Meter - Twin turbine mass flow meters work on the principle of fluid inertia. These mass flow controllers have a flow rate measurement section that includes a sensor bypass flow rate control valve and special circuitry.

In this video from Sierra youll learn the theory and working principles of thermal dispersion mass flow technology that is used in our gas flow meters. It is a method for damage control and protection of. Test Method for Determining Accuracy.

Video animation explaining the functions and features of Bronkhorsts MASS-STREAM Mass Flow Meters and Controllers for gases following the direct through fl. User programmable mass flow rate Pulse Output via SSR. A mass flow controller is designed and calibrated to control a specific type of liquid or gas at a particular range of flow rates.

All 3 user selectable analog input and output interfaces are standard. Some gases with a low CF coefficient can be measured even lower. The standard accuracy of the gas mass flowmeter is 05.

Transmitter Working On Heat dissipation technique calorimetric primary signal mass flow proportional independent of pressure and temperature. Flow control by volume flow such as flow meters and needle valves. Structure and operating principles.

Mass Flow Control Critical Terminology and Operation Principles for Gas and Liquid MFCs A mass flow controller MFC is a closed-loop device that sets measures and controls the flow of a particular gas or liquid. The thermal Mass Flow Meter or Controller is capable of providing direct measurement of mass flow as opposed to most other methods that measure volumetric flow and require separate measurements for temperature and pressure in order to calculate density and ultimately the mass flow. Industrial thermal mass flow meters also known as thermal dispersion or immersible thermal mass flowmeters comprise a family of instruments for precision measurement of total mass flow rate equation of a fluid primarily.

Thermal Mass Flow Sensors What Is Their Working Principle

Multi Gas Multi Range 50 Slm Mass Flow Controller

Laminar Flow Element Lfe For Flow Meters Bronkhorst

Horiba Fluid Measurement Control Mass Flow Controller

![]()

Schematic Of Flow Control Schemes For Mass Flow Controllers Used In The Download Scientific Diagram

Mass Flow Controller C F Fcon Co Ltd

Thermal Mass Flow Meter Working Principle Instrumentationtools

Mass Flow Controller C F Fcon Co Ltd

Mass Flow Controller Mfc Working Principle Bronkhorst

Horiba Fluid Measurement Control Mass Flow Controller

Mass Flow Controller C F Fcon Co Ltd

Horiba Fluid Measurement Control Mass Flow Controller

Mass Flow Controller Mfc Working Principle Bronkhorst

Comparing Gas Flow Instrument Technologies Alicat Scientific

How A Mass Flow Controller Works Youtube

Thermal Mass Flow Sensors What Is Their Working Principle

Mass Stream Thermal Mass Flow Controller Principle Of Operation Youtube

.jpg)